#social-physics

2018-10-11

patcon

21:02:47

@patcon has joined the channel

kevinphy

21:02:59

@kevinphy has joined the channel

shuyang

21:03:03

@sylin has joined the channel

yitzu

21:03:10

@yitzu7 has joined the channel

patcon

21:04:39

@patcon set the channel topic: Hover for details...

patcon

21:04:54

@patcon set the channel topic: Hover for details...

Docs: https://hackmd.io/txrNRnNVSW-jI0kFH_udXg

Docs: https://hackmd.io/txrNRnNVSW-jI0kFH_udXg

2018-10-12

patcon

12:39:25

Patrick Connolly

@sylin @yitzu7 re: our convo on the way to the MRT

https://hackmd.io/txrNRnNVSW-jI0kFH_udXg?view

- Forwarded from #vtaiwan

- 2018-10-11 01:37:08

- 1

patcon

12:39:47

Patrick Connolly

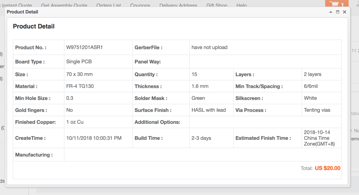

Do either of you have advice on how to move quickly with ordering a small batch of these circuit boards?

- @sylin did you say that you could pay and/or expense the cost to PDIS?

- Can anyone help guide us toward a circuit board vendor and getting a quote? (my research reveals that it's a very confusing choice without a guiding hand!)

- Forwarded from #vtaiwan

- 2018-10-11 12:43:07

patcon

12:40:09

shu yang lin

I can buy few out of my pocket, vendor needed though

- Forwarded from #vtaiwan

- 2018-10-11 13:40:44

shuyang

2018-10-24 16:44:11

for small batch pcb ordering I usually go to https://www.seeedstudio.com

patcon

2018-10-24 16:49:06

cool! we had some recommendations for pcbway, but these folks look friendly. talk tonight 🙂

patcon

13:09:06

hey @kevinphy, I was going back over my emails with David Shrier (on the open badge project), and realized it's probably most straightforward to open a public GitHub ticket with our questions. Mind if I do that instead of one-to-one email?

kevinphy

13:21:09

@patcon NP, just creating issue on GitHub sounds great.

patcon

2018-10-12 13:33:36

Ah shoot, sorry -- was in the process of doing that as well:

https://github.com/HumanDynamics/openbadge/issues/108

(apologies, I feel like I'm being overeager..! I'll try to slow down and talk things out more)

https://github.com/HumanDynamics/openbadge/issues/108

(apologies, I feel like I'm being overeager..! I'll try to slow down and talk things out more)

kevinphy

2018-10-12 13:45:40

No worry lol, keep moving forward and I’ll try to catch up!

patcon

13:33:36

Ah shoot, sorry -- was in the process of doing that as well:

https://github.com/HumanDynamics/openbadge/issues/108

(apologies, I feel like I'm being overeager..! I'll try to slow down and talk things out more)

https://github.com/HumanDynamics/openbadge/issues/108

(apologies, I feel like I'm being overeager..! I'll try to slow down and talk things out more)

GitHub

First off, thank you so so much for making this repo public and keeping it up-to-date. I've had such energizing conversations with people about working with the artifacts of your project. :heart: Co...

1

1- 💯1

1

1

kevinphy

13:45:40

No worry lol, keep moving forward and I’ll try to catch up!

2018-10-13

patcon

18:04:01

As I was reading the reply to our GitHub issue, I took some notes on questions that were raised:

https://hackmd.io/txrNRnNVSW-jI0kFH_udXg

Also, started pricing out the building of the programmer, and we could price out building one-off boards in the spreadsheet too (linked from hackmd)

https://hackmd.io/txrNRnNVSW-jI0kFH_udXg

Also, started pricing out the building of the programmer, and we could price out building one-off boards in the spreadsheet too (linked from hackmd)

patcon

2018-10-13 18:05:53

I figure maybe we could store up questions and check in with one another before asking that dude (who i imagine is pretty busy!)

patcon

18:05:53

I figure maybe we could store up questions and check in with one another before asking that dude (who i imagine is pretty busy!)

patcon

18:06:19

@kevinphy does taipei hackerspace have access to a laser cutter?

patcon

18:06:55

if so, any acrylic laying around?

kevinphy

18:08:38

We don’t have functional laser cutter (broken one is still waiting to be repaired). But we do have plenty commercial laser cutter stores for acrylic around here, less than 3 min by walk.

kevinphy

18:08:57

I think it’s around 2-3 shops

kevinphy

18:11:06

Taiyuan Rd. and this area support hardware materials at wholesale.

patcon

18:12:26

ok cool! sounds like we can sort it later. if you know the rough prices offhand (parts & labour), feel free to add it here:

https://docs.google.com/spreadsheets/d/1WTSAATEkbLkV2WBjTKi6NyAyRwMRTKHSMc90ohGy0Dc/edit#gid=0

https://docs.google.com/spreadsheets/d/1WTSAATEkbLkV2WBjTKi6NyAyRwMRTKHSMc90ohGy0Dc/edit#gid=0

kevinphy

18:12:26

kevinphy

18:13:44

Sure sure

patcon

18:15:37

anyhow, heading out for dinner, but talk soon!

patcon

18:16:28

oh! would you be interested to use your gear to help the media lab folks improve their docs? re: https://github.com/HumanDynamics/openbadge/wiki/Open-Badge-V3.0#building-a-programmer

GitHub

Contribute to HumanDynamics/openbadge development by creating an account on GitHub.

patcon

18:16:51

I mean, they're pretty good already, but it might be an excuse to build one of the badges on our own

- 🖖2

1

1

kevinphy

18:22:56

I think we could just fork repo into somewhere someone’s GitHub and create a brand new documentation for different purpose branch (to be used in g0v)?

kevinphy

18:23:28

If it works, we can push back to original repo

patcon

19:10:15

sure! we can request a g0v repo if we'd like

patcon

19:13:04

i'll be aiming to generalize them and push them upstream sooner rather than later though 🙂

2018-10-16

patcon

11:52:16

A respected brain/AI researcher named Jeff Hawkins has recently started communicating about his long-developing theory of how our brains work. It assumes spatial encoding is very foundational to all mental processing, including abstract thought. It relates to a really cool brain system that uses something called grid cells: https://youtu.be/mP7neeymcUY

Anyhow, just wanted to share, as it gives me confidence that the approaches of #holopolis (polis into VR) and these sociometric badges (polis into physical space), are on the right track for truly having public policy decision-making align with how our brains are wired to work :)

cc: @sylin

Anyhow, just wanted to share, as it gives me confidence that the approaches of #holopolis (polis into VR) and these sociometric badges (polis into physical space), are on the right track for truly having public policy decision-making align with how our brains are wired to work :)

cc: @sylin

2018-10-18

patcon

16:24:49

Hey @kevinphy! Just to sync up, I just wanted to officially commit to being at Taipei hackerspace for the next tues open house. Would that work for you, if we wanted to work on these badges?

And if so, would you want to come @sylin? 6pm onward

And if so, would you want to come @sylin? 6pm onward

- 🖖1

kevinphy

2018-10-19 14:52:08

Sure next tue perfect!

2018-10-19

kevinphy

14:52:08

Sure next tue perfect!

2018-10-23

patcon

15:02:05

@kevinphy when you planning to be at taipei hackerspace?

fiorella

15:02:08

@fiorella has joined the channel

patcon

15:02:21

@sylin or @fiorella, you interested in coming?

shuyang

2018-10-23 15:32:05

today? (sorry for being not responsive lately… I sent my mac to repair last week. forgot to install Slack on my temp laptop lol)

patcon

2018-10-23 15:36:59

yep, but only if you have time 🙂 no pressure, just thinking it'd be good for other ppl interested to meet, so it's not just me who knows everyone!

alternatively, @kevinphy are you coming to vTaiwan meeting tomorrow evening? And if we do @sylin, will there be any informal time to discuss possibilities?

alternatively, @kevinphy are you coming to vTaiwan meeting tomorrow evening? And if we do @sylin, will there be any informal time to discuss possibilities?

shuyang

2018-10-23 15:44:30

Then I will skip today. Thanks for asking! 🙂 but I will be there in this week’s vTaiwan. maybe a bit late… at 8pm or so, but I will be there.

shuyang

2018-10-23 15:46:38

Yes let’s talk about holopolis too. Will be cool to sync a bit on holopolis proj, also we just got two Holodeck access keys - can do something with that.

patcon

2018-10-23 16:24:57

ah cool! this thing? https://www.nvidia.com/en-us/design-visualization/technologies/holodeck/

Is there a permanent holodeck in Taipei?

Is there a permanent holodeck in Taipei?

patcon

2018-10-23 16:25:43

@kevinphy in case you were wondering: http://holopolis.pdis.tw/

patcon

2018-10-23 16:30:28

and this, for more detail: https://docs.google.com/document/d/17-TZX-A6ysES5VLb18kv2jmWqajkYURRZacmyQ5fPgk/edit

@sylin started the project (?) and i'd been informally trying to engage from Canada -- it's an attempt to use new tools and modes for policymaking. there are 3 "official" sub-projects of holopolis, started from within gov, but the whole idea is that it's an "open project", and people can start other initiatives from outside government (if I'm understanding correctly)

@sylin started the project (?) and i'd been informally trying to engage from Canada -- it's an attempt to use new tools and modes for policymaking. there are 3 "official" sub-projects of holopolis, started from within gov, but the whole idea is that it's an "open project", and people can start other initiatives from outside government (if I'm understanding correctly)

fiorella

2018-10-24 02:32:56

Sorry Patrick, I just read your message (I'm more responsive on fb). I was really busy today (or yesterday). See you at vTaiwan's hackathon!

patcon

15:03:09

@kevinphy I got paid, so I'd love to order some boards tonight if you're game, and if we can figure it out 🙂

kevinphy

2018-10-24 16:18:01

I can support with my visa card to order tonight!

patcon

2018-10-24 16:34:36

oh cool! ok, and i can pay you back!

patcon

15:07:19

we'll likely need to eventually create a little app that pulls data from the hub and puppets a pol.is conversation using this feature of the iframe embed:

https://docs.pol.is/usage/UserAuthorization.html#proprietary-auth

https://docs.pol.is/usage/UserAuthorization.html#proprietary-auth

patcon

15:14:33

hm. ok, so it's not documented, but I recall @colinmegill explaining that xid could be passed in and used to create new users: https://github.com/pol-is/polisClientParticipation/blob/304c9929ebbc0a3e1bf57122dd4798fd4c32a61d/api/embed.js#L42-L44

GitHub

:bar_chart: :heavy_check_mark: the participation view (viz and voting) - pol-is/polisClientParticipation

shuyang

15:32:05

today? (sorry for being not responsive lately… I sent my mac to repair last week. forgot to install Slack on my temp laptop lol)

- ❤️1

- 🛠️1

patcon

15:34:46

ok, i'll aim for then too!

patcon

15:36:59

yep, but only if you have time 🙂 no pressure, just thinking it'd be good for other ppl interested to meet, so it's not just me who knows everyone!

alternatively, @kevinphy are you coming to vTaiwan meeting tomorrow evening? And if we do @sylin, will there be any informal time to discuss possibilities?

alternatively, @kevinphy are you coming to vTaiwan meeting tomorrow evening? And if we do @sylin, will there be any informal time to discuss possibilities?

shuyang

15:44:30

Then I will skip today. Thanks for asking! 🙂 but I will be there in this week’s vTaiwan. maybe a bit late… at 8pm or so, but I will be there.

shuyang

15:46:38

Yes let’s talk about holopolis too. Will be cool to sync a bit on holopolis proj, also we just got two Holodeck access keys - can do something with that.

patcon

16:24:57

ah cool! this thing? https://www.nvidia.com/en-us/design-visualization/technologies/holodeck/

Is there a permanent holodeck in Taipei?

Is there a permanent holodeck in Taipei?

NVIDIA

A state-of-the-art VR collaboration platform for designers and teams. Design virtual worlds and sims, AI-augmented vehicles, and more.

patcon

16:25:43

@kevinphy in case you were wondering: http://holopolis.pdis.tw/

patcon

16:30:28

and this, for more detail: https://docs.google.com/document/d/17-TZX-A6ysES5VLb18kv2jmWqajkYURRZacmyQ5fPgk/edit

@sylin started the project (?) and i'd been informally trying to engage from Canada -- it's an attempt to use new tools and modes for policymaking. there are 3 "official" sub-projects of holopolis, started from within gov, but the whole idea is that it's an "open project", and people can start other initiatives from outside government (if I'm understanding correctly)

@sylin started the project (?) and i'd been informally trying to engage from Canada -- it's an attempt to use new tools and modes for policymaking. there are 3 "official" sub-projects of holopolis, started from within gov, but the whole idea is that it's an "open project", and people can start other initiatives from outside government (if I'm understanding correctly)

patcon

20:40:35

bah, i suck. omw! I'm going to stop at ba fang dumpling to grab quick food. want anything @kevinphy?

patcon

2018-10-23 20:41:08

or i could meet you there. the one just south of you

kevinphy

2018-10-23 20:58:30

I am okay and full! thanks!

Where are you now?

Where are you now?

patcon

2018-10-23 21:11:15

Just getting there is a sec hopefully. The one closest was closed :(

patcon

2018-10-23 21:31:45

Omg the traffics is the worst here :/ I'm sorry, I was so hungry, but this is really late

patcon

2018-10-23 21:37:31

OK parked. 5 min walk

patcon

20:41:08

or i could meet you there. the one just south of you

kevinphy

20:58:30

I am okay and full! thanks!

Where are you now?

Where are you now?

patcon

21:11:15

Just getting there is a sec hopefully. The one closest was closed :(

patcon

21:31:45

Omg the traffics is the worst here :/ I'm sorry, I was so hungry, but this is really late

patcon

21:37:31

OK parked. 5 min walk

2018-10-24

fiorella

02:32:56

Sorry Patrick, I just read your message (I'm more responsive on fb). I was really busy today (or yesterday). See you at vTaiwan's hackathon!

kevinphy

16:10:40

@patcon Finally! @imyentsen just joined.

I just forwarded @imyentsen your master thesis plan to @patcon. And your researches seem like all related!!

I just forwarded @imyentsen your master thesis plan to @patcon. And your researches seem like all related!!

kevinphy

16:18:01

I can support with my visa card to order tonight!

Ansin Law

16:18:57

Hello guys! I’m Ansin (Yentsen is my official name pronounced in Mandarin). I’m now working on my master’s thesis on democratic communication and user interface design. Just quickly read through the discussion and it seems that we share many interests in common!

Ansin Law

16:20:51

One of the benchmarks in my rough thesis plan is exactly Pol.is. Are you working on the development of it @patcon ?

shuyang

2018-10-24 16:47:16

can we find some of your work online? or a rough description of it?

Ansin Law

2018-10-26 21:19:43

Hello, just found that I missed your msg. sorry for late reply! The plan is at a very early stage. you can find my plan here: https://yentsenliu.com/master-thesis-plan

patcon

16:30:17

hey @imyentsen! yay! glad you're here! I'm not working on the development of it more than anyone else who's interested in it and technical 🙂 it's open source, and they are welcome to contributions to make it more friendly for others to run and use it:

https://github.com/pol-is

https://github.com/pol-is

GitHub

:milky_way: AI powered surveying tool for open ended feedback and participatory democracy - Polis

patcon

16:31:23

(i'm trying to find a resource that feels very related to your project -- it's like argument mapping, but for the structure of conversations -- a notation of sorts. a firend in toronto @nategerber on twitter -- used to be obsessed with it. he is a facilitation professional, so it's kinda related to his passion)

patcon

16:34:36

oh cool! ok, and i can pay you back!

patcon

16:41:08

@imyentsen this might be up your alley: http://ncdd.org/rc/item/2884/

NCDD Resource Center

Structured Dialogic Design (SDD) is the dialogue and decision-making methodology used by the Institute for 21st Century Agoras and others in their 'co-laboratories of democracy.' Laborato…

- 🙂1

patcon

16:41:29

It strikes me as an innovation in the spirit of vtaiwan (a process that hacks our psychology and ways of interacting in groups)

patcon

16:42:29

but the difference is that they embodies no open culture principles -- their practice uses proprietary software, paid training, and professionalized facilitators -- and so their movement died on the vine

patcon

16:43:49

vtaiwan, on the other hand, is about creating a movement of citizen facilitators, and the process itself is open and changeable. the process of building and refining vtaiwan is its own meta-process outside the scope of any one iteration (ie. of any one consultation on a specific topic)

shuyang

16:44:11

for small batch pcb ordering I usually go to https://www.seeedstudio.com

seeedstudio.com

Electronics products and services for Makers to Engineers. Fusion PCB manufacture, PCB Assembly, CNC milling services and more. Affordable and reliable. Realise your ideas with Seeed Studio.

shuyang

16:47:16

can we find some of your work online? or a rough description of it?

patcon

16:49:06

Replied to a thread: 2018-10-12 12:40:09

cool! we had some recommendations for pcbway, but these folks look friendly. talk tonight 🙂

Ansin Law

16:54:25

yeah, it looks super interesting! I haven't started to have an exhaustive review on the literature and the current available services using augmented mapping tho, but Kialo and Pol.is are two of the best I have seen by far. Just wonder — how do you think of the current interface or experience? what do you want to do for making it better?

Ansin Law

16:55:28

I agree with your point — open culture matters!

patcon

17:05:59

hm. maybe we could speak in person? big questions. i'm largely happy with the polis interface, but my understanding is that it needs some considerations for the UI so that it is more statistically significant and not misleading. the polis team was working on way to help with crowd-assisted moderation -- it's all manual right now

patcon

18:14:11

Where you living? You're welcome to come tonight if nearby, but we can coord another if not 🙂 maybe a tues/Thurs open house at Taipei hacker space

1

1

patcon

2018-10-26 22:41:50

Ah shoot, just realized that you're in helsinki, huh? https://www.linkedin.com/in/yentsenliu/?originalSubdomain=fi

patcon

19:45:15

Room 9A btw

patcon

19:45:27

just started and went throught intros, but drop by whenver

patcon

19:45:47

@kevinphy any thought on when you might come by?

patcon

19:49:46

added us to the agenda for sometime late tonight: https://g0v.hackpad.tw/20181024-vTaiwan-xHUkJdMjomp

kevinphy

20:00:32

@patcon arrived around the campus, heading to the building

ael

20:00:35

@aelcenganda has joined the channel

patcon

20:00:57

ok cool! i added us in the agenda as a "share" item

patcon

20:03:06

@kevinphy you hungry? can i save you a piece of pizza

ky

20:07:28

@lisa has joined the channel

hychen

20:10:23

@hychen has joined the channel

billy3321

20:11:22

@billy3321 has joined the channel

Fang

20:11:27

@fang has joined the channel

patcon

20:28:47

GitHub

Contribute to HumanDynamics/openbadge-analysis-examples development by creating an account on GitHub.

patcon

20:56:18

@kevinphy want to go work in the next room?

kevinphy

20:56:59

Sure let’s order boards

2018-10-25

patcon

15:32:55

<!here> updated hackmd pad with notes from last night's meeting (incl action items) 🎉

https://hackmd.io/txrNRnNVSW-jI0kFH_udXg?view#Meetings

(feel free to edit/add to it)

https://hackmd.io/txrNRnNVSW-jI0kFH_udXg?view#Meetings

(feel free to edit/add to it)

patcon

2018-10-25 16:35:03

added a "Contributing" section to hackmd pad

patcon

16:21:09

hey @kevinphy, what's your github username?

kevinphy

2018-10-25 16:47:34

You’ve already found it 😆

patcon

2018-10-25 16:48:20

heh

patcon

16:35:03

added a "Contributing" section to hackmd pad

kevinphy

16:47:34

You’ve already found it 😆

patcon

16:48:20

heh

patcon

16:48:55

re: using platforms for shared hardware projects. https://github.com/HumanDynamics/openbadge/issues/109

GitHub

Hi again @OrenLederman! A few of us have been talking and meeting to work on this. (We keep notes fwiw) We came across some websites that we were hoping to use so that it&#39;s simpler for the next...

patcon

16:56:56

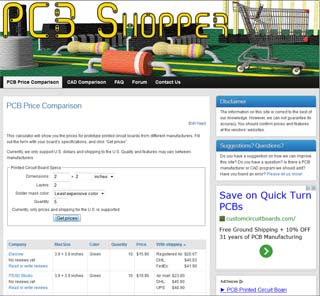

not sure its worth it here, but pretty rad: http://pcbshopper.com/

pcbshopper.com

PCBShopper is a price comparison site for printed circuit boards. Enter your PCB's specs and immediately see prices from more than 20 PCB manufacturers.

patcon

18:34:38

Hackaday

If you are lucky enough to encounter a piece of homebrew electronics from the 1950s, the chances are that under the covers the components will be assembled on solder tags, each component with long leads, and chassis-mounted sockets for tubes. Easy to assemble with the most agricultural of soldering irons. Open up a home build from the 1960s or early 1970s, and you might find the same passive components alongside germanium transistors mounted through holes in a curious widely spaced stripboard or even a home-made PCB with chunky wide tracks. Solder tags aplenty in a commercial transmitter from the early 1960s Cutting-edge 1970s homebrew By the late 1970s and early 1980s you would find a more familiar sight. Dual-in-line ICs through-hole on 0.1″ spaced stripboard, and home-made PCBs starting to appear on fibreglass board. Easy to use, easy to solder. Familiar. Safe. Exactly what you’ll see on your breadboard nearly forty years later, and still what you’ll see from a lot of kit manufacturers. Nice and familiar, a through-hole Nicholas Zambetti CC BY-SA 3.0But we all know that progress in the world of electronic components has not stood still. Surface-mount components have a history going back to the 1960s, and started to appear in consumer equipment from the end of the 1980s. More components per square inch, smaller, cheaper devices. Nowadays they are ubiquitous, and increasingly these new components are not offered in through-hole versions. Not a problem if your experiments are limited to the 741 and the 555, but something that rather cramps your style if your tastes extend to novel sensors for a microcontroller, or RF work. This development has elicited a range of reactions. Many people have embraced the newer medium with pleasure, and the project pages are full of really clever SMD projects as a result. But a significant number have not been able to make the jump to SMD, maybe they are put off by the smaller size of SMD components, the special tools they might require, or even the new skills they’d have to learn. When you sell a kit with SMD components these are the reactions you will hear from people who like the kit but wish it was available in through-hole, so this article is for them. To demystify working with SMDs, and to demonstrate that SMD work should be within the grasp of almost anyone who can wield a soldering iron. But They’re So Tiny! Tiny SMDs – fortunately most of which you will not have to worry ’s likely to be the first reaction from a lifelong through-hole solderer. SMD parts are often very small indeed, and even those with larger packages can have leads that seem as numerous and thin as the hairs on a cat when seen with the rabbit-in-the-headlights panic of the uninitiated. But it is important to take a step back and understand that not all SMDs are created equal. Some of them are grain-of-sand tiny and only hand-solderable by those with God-like powers, but plenty of devices are available in SMD packages large enough for mere mortals. So don’t worry when you look at a board covered with grain-of-dust-sized components. Very few people could attempt that level of construction, your scribe certainly can’t. (We await commenters claiming to routinely hand-solder thousand-pin BGAs and 01005 chip components with anticipation, however such claims are useless without proof.) Instead, concentrate on the SMD packages you can handle. SMD chip component packages are refered to by a number that relates to their dimension. Confusingly there are both metric and imperial versions of the scheme, but the format is the same: length followed by width. Consider the picture above with the PCB and the tape measure, it’s the underside of a Raspberry Pi model B+, and will have been assembled by a robotic pick-and-place machine. The majority of the components are very tiny indeed, but you will notice L3 as the black component towards the bottom left that looks huge compared to its neighbours. That package is a “1008”, 0.1 inches long by 0.08 inches wide. It’s still tiny, but imagine picking it up with a pair of tweezers under a magnifying glass. Not so bad, is it. You’ve probably handled plenty of things in that size range before, do SMD parts seem so scary now? The larger components – 0805, 1008, and 1206 – are surprisingly within the grasp of the average maker. But I need all sorts of special tools! Retro Populator, a homebrew pick-and-place machine we featured back in 2014In a commercial environment an SMD device will be assembled by machine. Glue or solder paste will be printed in the relevant parts of the board, and a robotic pick-and-place machine will retrieve components from their tape packaging and automatically place them in their correct orientations. The board will then be soldered all-at once, either in a reflow oven or by a wave soldering machine. If you’re new to SMDs you are unlikely to have any of this kit just lying around on your bench. There are self-built pick-and-place machines and a host of self-built reflow ovens, but it’s safe to say they’re still quite an advanced thing to have. You’ll also see all manner of commercial kit aimed at the bench-top SMD constructor. Hot air soldering stations or SMD bits for conventional irons, all of which are very useful but come with a hefty price tag. The good news is that you don’t need any of these special tools to dip your toe into the SMD water. You almost certainly already have everything you need, and if you don’t then very little of what you lack is specifically for SMD work. If you have the following items then you are good to go: A basic SMD soldering toolkitA good light source. Even the larger SMDs are still pretty small. Plenty of light ensures you will be able to see them clearly. A good downward pointing desk lamp should suffice. A clear high-contrast surface. Because SMDs can be difficult to see, it helps if they are manipulated over a bright white surface. A fresh sheet of white printer paper on a desk makes a suitable working area. Good hands-free magnification. Unless you are fortunate enough to have amazing eyesight, you will need a decent magnifier to work with surface-mount components. The “Helping hands” type on a stand are suitable. A very small flat-blade screwdriver. You will need this to hold surface-mount components down while you solder them. A good-quality set of precision metal tweezers. You will need these for picking up, manipulating, and turning over surface-mount devices. A fine-tipped soldering iron. If you have a standard fine tipped iron suitable for use with conventional 0.1” pitch through-hole components then you should be well-equipped. That said there is one special tool that might be worth your consideration. Holding an SMD device while soldering it can sometimes seem like a task that needs three hands, so one or two tools can be found to help. Fortunately this is something you can build yourself. Take a look at the SMD Beak, a weighted arm for example, or your scribe’s spring clamp third hand. I’m sorry, this is just beyond my soldering skill level Desolder braid and plenty of flux are your is easy to imagine when you are looking at an SMD integrated circuit that its pins are just too small and too close together, you couldn’t possibly solder them by hand. The answer is that of course you can, you simply need to view how you solder them in a different way. With a through-hole IC you solder each 0.1″ pitch pin individually. It is something of a disaster if you manage to put a solder bridge between two pins, and you race for your desolder pump or braid. With a surface-mount IC by comparison there is little chance that you as a mere mortal could sol…

patcon

2018-10-25 18:44:00

tl;dr - there are some 0603 size surface mount parts (0.06" x 0.03"), which make this seem waaaaaay too small to try to solder ourselves

looks like, as mere mortal, we should just research pre-assembled

looks like, as mere mortal, we should just research pre-assembled

kevinphy

2018-10-25 21:04:57

0603 is exactly doable for 10 pics. No worry!

We’re able to make it in Hackerspace with suitable equip.

We’re able to make it in Hackerspace with suitable equip.

kevinphy

2018-10-25 21:05:39

We have microscope for soldering in the space!

patcon

2018-10-25 22:26:06

cool! ok, I stand corrected 🙂

I'll still price all options

I'll still price all options

patcon

18:44:00

Replied to a thread: 2018-10-25 18:34:38

tl;dr - there are some 0603 size surface mount parts (0.06" x 0.03"), which make this seem waaaaaay too small to try to solder ourselves

looks like, as mere mortal, we should just research pre-assembled

looks like, as mere mortal, we should just research pre-assembled

kevinphy

21:04:57

0603 is exactly doable for 10 pics. No worry!

We’re able to make it in Hackerspace with suitable equip.

We’re able to make it in Hackerspace with suitable equip.

kevinphy

21:05:39

We have microscope for soldering in the space!

patcon

22:26:06

cool! ok, I stand corrected 🙂

I'll still price all options

I'll still price all options

2018-10-26

patcon

06:06:40

playing around with shared bom's on mouser:

https://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=e7238b7ae4 (just for testing, bc need to re-source parts)

playing with PCBWay shared projects here:

https://www.pcbway.com/project/member/shareproject/?bmbno=W230614A

Order 5 unassembled programmer PCBs is USD$9 with shipping. Listed here for ordering: https://www.pcbway.com/project/shareproject/Rhythm_Badge_Programmer.html

20 unassembled badge boards at USD$47 (can't see shipping until assembly quote comes in).

and looking into seeed's community site makes me realize its only for kits -- not made for ordering fabricated boards: https://project.seeedstudio.com/projects

https://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=e7238b7ae4 (just for testing, bc need to re-source parts)

playing with PCBWay shared projects here:

https://www.pcbway.com/project/member/shareproject/?bmbno=W230614A

Order 5 unassembled programmer PCBs is USD$9 with shipping. Listed here for ordering: https://www.pcbway.com/project/shareproject/Rhythm_Badge_Programmer.html

20 unassembled badge boards at USD$47 (can't see shipping until assembly quote comes in).

and looking into seeed's community site makes me realize its only for kits -- not made for ordering fabricated boards: https://project.seeedstudio.com/projects

Ansin Law

21:19:43

Hello, just found that I missed your msg. sorry for late reply! The plan is at a very early stage. you can find my plan here: https://yentsenliu.com/master-thesis-plan

patcon

22:41:50

Ah shoot, just realized that you're in helsinki, huh? https://www.linkedin.com/in/yentsenliu/?originalSubdomain=fi

2018-10-30

patcon

13:21:12

@kevinphy just got an email from oren. any thoughts? i feel we should still plow forward with our own plans, but is the sort of thing he's talking about of interest to you as well?

https://hackmd.io/2ZxC4fFXRDqnqetMfWDKRw?view

https://hackmd.io/2ZxC4fFXRDqnqetMfWDKRw?view

kevinphy

15:46:42

I just asked my friend saying http://xfactory.io (strong relationship with Seeed) in Shenzhen is extremely possible to support and fund this project for us.

patcon

2018-10-30 15:59:59

thanks! skimmed quickly and looks awesome! Will dig more later

patcon

2018-10-30 16:00:31

and wait what do you mean by "fund"? As in they'd cover the costs of what?

patcon

2018-10-30 16:01:16

and does your friend have any special connection to cfactory, or is it that they're a big fan?

kevinphy

2018-10-30 16:16:00

Yeah! It seems that getting the fund for the project you are building from Xfactory is most likely than from Media Lab.

kevinphy

2018-10-30 16:16:10

Let me ask about connection

patcon

2018-10-30 16:38:10

Re: funding. Was thinking about this one as a possibility: https://grants.g0v.tw

patcon

2018-10-30 16:38:55

My sense is that the topic area is something that those running the grant would be supportive of (though can't speak for the judges)

patcon

15:59:59

thanks! skimmed quickly and looks awesome! Will dig more later

patcon

16:01:16

and does your friend have any special connection to cfactory, or is it that they're a big fan?

patcon

16:01:54

@patcon set the channel topic: Hover for details...

Docs: https://hackmd.io/s/H1mc0oj9Q

Docs: https://hackmd.io/s/H1mc0oj9Q

kevinphy

16:16:00

Yeah! It seems that getting the fund for the project you are building from Xfactory is most likely than from Media Lab.

kevinphy

16:16:10

Let me ask about connection

patcon

16:38:10

Replied to a thread: 2018-10-30 15:46:42

Re: funding. Was thinking about this one as a possibility: https://grants.g0v.tw

patcon

16:38:55

My sense is that the topic area is something that those running the grant would be supportive of (though can't speak for the judges)

patcon

16:41:03

ipa

[順便預告] g0v grant 2019 將在 `十二月上旬` 開始投稿,截止應該是一月上旬。新的細則還在修訂,過陣子會請社群 open review。

- Forwarded from #general

- 2018-10-27 11:16:45

patcon

21:43:14

omg, just skimming this so far, but it's either genius or batshit crazy:

http://socialfabric.city/home/about-the-book/

> This chapter proposes that the only connection between things of different materialities is meaning – not an idea of meaning as a stable ‘identity’ or ‘essence’ but as meaning as a connection.

http://socialfabric.city/home/about-the-book/

> This chapter proposes that the only connection between things of different materialities is meaning – not an idea of meaning as a stable ‘identity’ or ‘essence’ but as meaning as a connection.

The social Fabric of Cities

The Social Fabric of Cities puts together an approach to cities and how they are part of social life – in fact, a tripartite approach to cities […]

2018-10-31

patcon

19:40:50

@kevinphy heyo. whatcha up to?

kevinphy

19:55:09

@patcon I cannot show up tonight but I can work with you remotely

kevinphy

19:56:55

@patcon I haven’t bought components from Taobao separately cause we are asking fund for this projects in these days. What would you like to do next?

kevinphy

19:57:57

Checking resources of that Kitspace can provide now…

patcon

19:59:27

Heh no worries. I've for a PR for kitspace in queue

patcon

20:00:28

Tonight is a "real" vTaiwan meeting and a acquaintance from out of town is coming to see it, so I might not be able to come online fully until later :(

- 🖖1

patcon

20:02:41

But for now, Im sorting out what octoparts common parts registry is, so that this one-click BOM plugin will work (and offer alternatives when the specific part runs out). Sorry, still figuring out how all this supply chain stuff works longterm

- 💯1

kevinphy

2018-10-31 21:06:28

Yeah for longterm which is much more important!

patcon

20:04:16

i've got the badge boards in my cart for $47 for 20, and 5 programmer boards for $5. Should we just order them? I'm happy to pay the board price without any seeed partnership, since it's pretty cheap. (plus it takes the longest time to arrive, i think?)

patcon

20:04:26

(i can give you my login)